Description

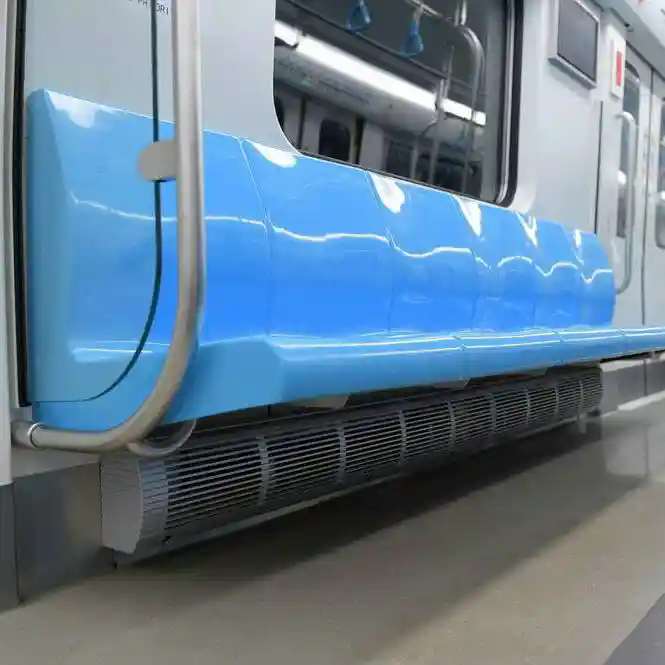

The choice of FRP (glass fiber reinforced plastic) as the main material for subway seats is mainly based on the following key factors:

1. High strength & lightweight

Strong impact resistance: FRP is made of glass fiber + resin, which is stronger than ordinary plastic and can withstand dynamic loads such as frequent subway starts and stops and crowded passengers.

Light weight (density 1.5~2.0 g/cm³), 60%~70% lighter than steel, reducing the weight of the carriage and reducing energy consumption.

2. Corrosion-resistant & maintenance-free

The subway environment is humid and may be exposed to detergents, sweat stains, etc. FRP is acid- and alkali-resistant and rust-proof, and will not rust or corrode like metal seats.

Long service life (more than 10 years) and low maintenance cost.

3. Fire safety (in compliance with rail transit standards)

By adding flame retardants, FRP can reach B1 flame retardancy (GB 8624) or EN 45545 (EU standard), with less smoke and low toxicity when burning, ensuring the safety of passengers in the event of a fire.

4. Flexible design & beautiful and easy to clean

Strong plasticity: can be molded into various shapes (such as streamlined, curved), adapting to different subway car designs.

Smooth surface: anti-fouling, easy to clean, suitable for high-frequency public transportation.

Various colors: different appearances (such as imitation metal, matte) can be achieved through spraying or lamination.

5. High cost-effectiveness

The initial cost may be higher than ordinary plastics, but the long-term comprehensive cost is lower than stainless steel or aluminum alloy (due to maintenance-free and aging-resistant).

6. Comfort (better than metal)

Good heat insulation: Unlike metal seats, which are cold in winter and hot in summer, the ride is more comfortable.

Moderate elasticity: Slightly softer than hard plastic or metal, more comfortable for short-distance rides.

Why don’t all subways use stainless steel or plastic?

Stainless steel: Although durable, it is heavy, cold to the touch, and expensive, suitable for some high-end lines.

Ordinary plastic: low strength, easy to age, poor fire resistance, and does not meet subway safety standards.

Fiberglass has achieved the best balance between strength, weight, safety, and cost, so it has become the mainstream choice for subway seats.

Summary

Glass FRP has become an ideal material for subway seats due to its advantages such as high strength, light weight, corrosion resistance, fire resistance, easy cleaning and cost control, taking into account safety, economy and comfort.

Contact Us

E-mail:sales@miyabifrp.com

If you are interested in any of Fiberglass products, please contact me by email and we will be happy to quote our lowest price as soon as we receive your detailed request.