(1) In order to achieve the accuracy of glass pipe installation and ensure uniform stress after pipe installation, the pipe fittings can be produced on site by professionals according to the site size.

Since FRP is a composite material, there are many factors that affect its corrosion resistance and construction quality. At the same time, in addition to the prefabrication of some pipe fittings on site, most of the pipe fittings, supporting processes and connections are hand-made paste on site, which is greatly affected by external conditions. When performing on-site presets, the JAL FRP reminds you of the following:

A. If the glue phenomenon occurs, one may be that the viscosity of the resin is too small, and 2% to 3% of active silica powder may be appropriately added; the second may be uneven batching, and the resin liquid should be fully stirred when preparing the resin liquid; Insufficient dosage, the amount of curing agent should be adjusted appropriately.

B. If the surface of the product is sticky, it may be that the cross-linking agent in the resin on the surface of the product volatilizes too much, and the stupid ethylene volatilization in the resin causes the ratio to be out of adjustment, resulting in no curing. The prevention method is to avoid excessive temperature before the resin is gelled; control ventilation and reduce volatilization. Second, it may be that the air humidity is high, and water has retardation and inhibition of the curing of the resin. Therefore, it is best to choose a weather with a relatively low humidity for construction. Special measures should be taken in rain and snow.

C. If there are many bubbles in the product, one may be too much resin and the bubble content of the glue is too much, so the amount of glue should be strictly controlled. At the same time, pay attention to the way of stirring to prevent excessive bubbles.

D. If the product is delaminated, check whether all the glass cloth is dewaxed or damp. Use “three no” glass cloth and dry it before use. At the same time, it is necessary to check whether the amount of glue is insufficient or the glass cloth is not compacted. When making paste, use enough glue, apply it with force, make the laminate compact, and get rid of the bubbles.

E. If the curing is incomplete, the amount of the curing agent is insufficient or invalid. After the inspection, the original paste is removed and the paste is re-applied.

(2) Cutting of FRP pipe, draw the cutting line at the cutting place, including cutting the cutting line, the through cutting line connected with the cutting hole, and drawing the position of the cutting line with the angle grinder equipped with the cutting saw blade. Cut the pipe or open the hole. The cut should be flat, the cut size should be ±2mm, and coated with resin. When cutting holes in glass steel pipes, square holes shall not be opened.

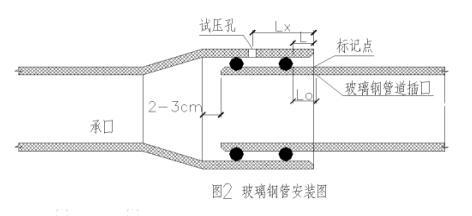

(3) When the pipe is down, the FRP pipe socket should be in the direction of the incoming water. In order to facilitate the exhaust when the nozzle is pressed, the test tube should be placed directly above the glass tube. The allowable deviation is 5mm. When the glass steel pipe is placed in the groove, it shall not collide with the groove wall. The transportation pipe inside the groove shall not disturb the natural foundation, and each pipe is staggered by 0.4 m in the direction of the groove.

(4) Thoroughly clean the surface, groove and rubber ring of the glass steel pipe before installation, and apply the lubricant to the rubber ring, then put it into the groove from the lower part without any distortion, and check the overall rubber ring seal in place by hand. .

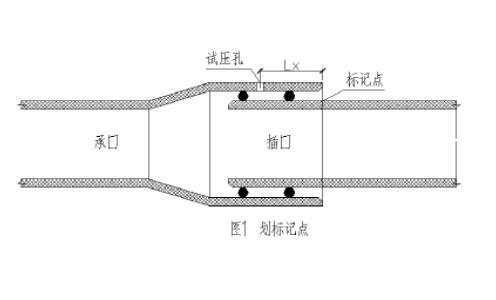

(5) Mark points and bumps. Take the Lx value from the center of the pressure test hole of the socket. In the direction of the ring of the two aprons of the socket to the direction of the ring of the socket, evenly mark the points. Installed by manual chain slamming method. Push the socket slowly into the socket until the end line of the socket coincides with the marked point. That is, the installation is in place.

(6)) After installation, use a steel ruler to detect the distance from the marked point to the outer wall of the nearest seal ring. The difference between the control and L is ±3mm.